- Prologue

- Iron-coal industry Location factors

- Iron Industry: three locations

- Factor: Empty Wagons

- Factor: Coking coal Shortage

- Factor: Technology

- Industrial Inertia

- Factor: strategic reasons

- Factor: Developmental policies

Iron-coal industry

- Iron ore + coke + limestone ==heat==> pig iron.

- pig iron=more processing=>cast-iron, wrought iron, steel and variety of alloys

Therefore, Essential inputs are:

- iron ore, coking coal and limestone

- water for cooling

- energy for heating

Steel industry also requires dolomite, manganese etc. but in small quantities=> their presence is not the main deciding factor for the location.

The three locations

- Near Forest

- Near Coalmines

- Near Coastal Areas

#1: Near Forest

- Until the end of medieval period, iron production was done on small scale.

- Energy was immobile (No wires to move electricity, No trains to move coal).

- To produce five tons of iron, you had to chop down one acre of forest to get sufficient charcoal.

- Therefore, wood supply=primary factor for deciding location. And smelters were usually setup near forest areas

- Even in Modern times, Visvesvaraya Iron and Steel Plant (Karnataka) was setup near jungle to get wood-charcoal. (Later switched to hydro-electricity from Sharawati river)

#2: Near coal fields

During the Industrial Revolution, iron and steel industry were setup near coalmines, due to following reasons:

- The coalfield region had a tradition of iron working based on charcoal as a result coalfield areas already had the labour and technology.

- In Britain, iron ore was found embedded with coal seams= same area provided both iron ore + coal

- During that era, to process 1 tons of iron ore, you needed 8-12 tons of coal. Railway engines were also inefficient. So, weight-wise, it was cheaper to transport iron ore to coalfields rather than transporting coal to iron ore site.

| Germany | Ruhr Valley, Saxony region |

| Britain | Lancashire, York shire, South Wales |

| United States | Appalachian-Pennsylvania-great Lakes |

| Australia | New South Wales region |

| China | Wuhan, Anshan, Chongqing |

by the way,

Why do we need “Coking coal”?

Because Iron ore=has iron oxide. But We’re only interested in iron. So, we’ve to get rid of the “oxide” part.

- Then how can we remove the “oxide” part? Ans. Make him marry with carbon and form “Carbon dioxide”.

- But where will you get the carbon? Ans. Coking coal. Because Coking coal has high concentration of carbon, compared to cheap varieties of coal like Lignite. Therefore you’ve to mix the coking coal with iron ore.

Iron Ore (Iron Oxide) + Coking Coal (source of Carbon) + Limestone (reducing agent)=heat*=> Iron + CO2 + slag.

*for heating you can use other variety of coal / even electricity.

#3: Near coastal areas

- By early 20th century the coal and iron ore mines in US-Europe started getting depleted. So, they started importing iron ore from other countries.

- As a result the iron space and steel industry started moving toward coastal sites to reduce cost of transporting ores from port to factory via railways.

| Japan | Iron steel industry is developed @coastal areas/port location because they rely on imported coal and iron-ore. E.g. steel industry in Osaka-Kobe |

| India | Steel plants @Vishakhapatnam, Ratnagiri, Mangalore |

| Malaysia | Has iron ore but not enough coalTherefore steel plants located near coastal area to get imported coal @minimum transport cost. |

| USA | In the coastal cities of Cleveland, Detroit, Chicago (using imported ores from Canada) |

Factor: Empty Wagons

- Ural=rich iron ore deposit

- Kuznetsk Basin in Western Siberia = rich coal deposits- sent to Ural region by Railways.

- The returning wagons after emptying coal, bring iron ore from Ural region.

- Result=> iron-steel industry developed @both places.

- Just like Ural-Kuznetsk, In India, Bokaro and Roukela steel plants:

- Trains bring iron ore from Rourkela => Bokaro

- and return with Coal from Bokaro =>Rourkela

- This optimizes the use of transportation (because wagons are never empty), and helped in growth of iron-steel industry @both places.

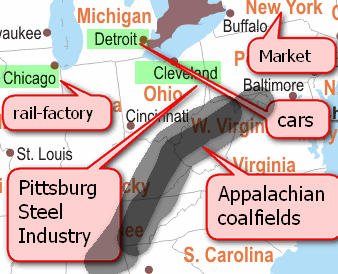

- Pittsburgh (Pennsylvania State) =steel industry was started using local iron ore and coal.

- But Local iron ore depleted so they started importing iron ore from Lake Superior region

- Problem: ships would bring iron ore but on their return journey, they’d be empty=> uneconomic use of transport.

- So, they started transporting Pittsburg coal to Lake Superior region in those returning ships=>steel industry developed in the lake region as well.

- But Since Pittsburgh itself is not a coastal city, so the coal/iron had to be transported to a port (Cleveland) first using railways.

- Thus, Cleveland (Ohio State) didn’t have iron ore or coal, yet got access to both => iron-steel industry developed in Cleveland. Same reason for Duluth in Minnesota.

Factor: Coking coal Shortage

Sweden has high quality iron ore, yet it specializes in non-ferrous metallurgy and light engineering, (rather than iron-steel industry), why?

- Because Sweden lacks cocking coal.

- Sweden exports its own iron ore to Ruhr (Germany) and in return imports pig iron from Ruhr.

- Then Sweden converts imported German Pig iron into steel, using electrical furnaces. (Advantage: cheap hydroelectric power, because Sweden = hills + fast flowing rivers).

- but since imported pig iron=costlier (than if they had made it locally)=> the steel thus manufactured, is used for making high value items e.g. Volvo Cars, Bofors Guns etc.

Factor: Technology

New technologies for steel production reduced the “pull” factor of coalmines in deciding location. For example:

| Open hearth system | even scrap metal can be used to make steelreduced fuel consumptionEven natural gas can be used. |

| Oxygen converter process | Further reduced coal/energy requirement. |

Combined with the invention of electric smelters, technology helped in development of Mini-steel plants near industrial cities (And away from iron-coal reserves).

Industrial Inertia

- Today, coal is not the only source of energy. We’ve natural gas, hydel electricity even nuclear power.

- + Thanks to new technologies in steel production, you don’t need massive amt. of coking coal.

- But still traditional industrial areas are located in and around the coalfields- sometimes even after the coal mines have exhausted, these industries are not shifting to a different location. Example Lancashire in UK; Ruhr in Germany; Pittsburg in USA.

- When industries don’t move away from an area, despite the locational disadvantage= this phenomena is called industrial inertia.

Inertia due to Government Policy

- The industrialists in old area usually have deep pockets and political connections so they lobby to government for favorable protectionist policies +large labour population in old area=vote bank.

- For example, Pittsburg is not a coastal city and nearby coal-iron ore reserves are getting depleted=> it was becoming more expensive to produce steel using imported iron-ore.

- But then Pittsburg industrialists lobbied, and US government made steel-pricing policies like “Multiple Basing system”, “Pittsburg plus” etc. (in the early 1900s).

- The impact of such policies => even if you can make cheaper steel in some other place of US (e.g. Southern Coastal areas), you still need to sell it @prices equivalent of Pittsburg steel industry. This demotivates entrepreneurs from setting steel-factories elsewhere, because they can’t sell their product cheaper than Pittsburg, to attract more customers.

Industrial Inertial in India

In July 2013, POSCO (Korean steel giant), pulled out from the steel-mill project in Karnataka worth almost $6 billion FDI, due to bureaucratic red tapes in environmental clearances and land acquisition. We can only speculate the vested interests and powerplay going on behind the curtains involing bureaucrats, politicians and mining mafias.

Factor: strategic reasons

USA

After WW2 and from the lessons of Aerial bombings destruction in Britain, US government decided that it was not wise to let entire steel-industry concentrated in the East (Great Lakes-Pittsburg region). Therefore, some plants were setup in the west (California). They get coal from Utah and Iron Ore from Eagle Mountains.

USSR

- Before Second World War, Ukraine-Donbas region was famous for iron steel and heavy industry.

- But these region suffered great destruction during Second World War. (as the Enemy Germans came from the West.)

- Due to this bad experience, the Soviet government adopted a policy to disperse Soviet industries on the Eastern side, towards the Pacific coast.

Factor: Developmental policies

| India |

|

| China |

|

Although Mao’s “backyard” idea was an #Epicfail, we’ll see in the next article on steel industries!

water4cooling @ salem plant – thalavaipatti, selatthamapatti yeri, pattapatti lake

sir wen u r coming wid the rest of industries…….only three months to go……sir plz fast..

very helpful n updated on world geo;;;;thnx mrunal and team members

I need to know if there is any specific geographical reason ( like iron formation) for distribution of iron ore in India and around world. Like major iron ore deposits in Indian are found on eastern side.

So with specific reason it will be easy to get through iron ore distribution across the world having nearly similar conditions.

Please answer

If the magma is basic then magma contains less silica and more iron , magnesium. When it will goes out from earth it make plateu like chhota nagpur plateu

hello mrunal

when can we expect the next two installment of the Geo series ??

Thankx for ur articles

Its helping me immensly

hi..when will you publish remaining portions for geo…eagerly awaiting!!

hello sirs related to plz publish factors related to tertiary plz…thr is hardly time left plz sir …

sory fr typing error..plz publish factors related to tertiary industries…thanks awaiting…

Mrunal Sir, u r doing a great service to all civil service aspirants with such useful articles..any other person would have charged a hefty fee for all this material..Thanks a lot!!

Dear Sir,

I think by mistake you have written limestone as reducing agent,while it actually act as a flux and Coke act as reducing agent..Please specify sir.

Mrunal bhai, no words can tell how your works cool off fear about each and every topic.

“Thank you so much”.

It was useful thank you sir

hello sir, I want geography notes handouts material on location of industry